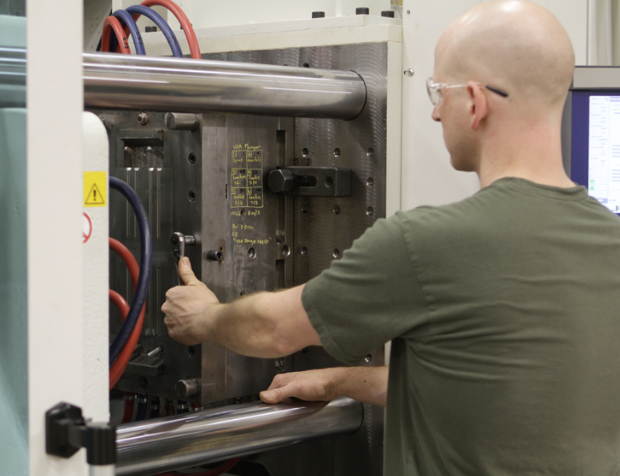

How to Manage Part Line Wear in an Injection Moulding Tool

- equipedesign

- Aug 6, 2025

- 5 min read

Injection Moulding is a highly efficient process for producing complex plastic parts, but like any manufacturing method, it comes with its own set of challenges. One common issue is part line wear, which can lead to defects, dimensional inaccuracies, and increased maintenance costs.

Understanding how to manage and mitigate part line wear is crucial for maintaining tool longevity and ensuring product quality.

As designers, we are most interested in the plastic parts we design and how they perform for fit, form and function. As the tool produces these parts, an understanding of the myriad of tooling and moulding process choices that determine the tool design and fabrication which directly affect the outcome. In turn, our part satisfaction and that of our customer.

In this blog, we’ll explore the causes of part line wear, its effects, and strategies for effective management.

Understanding Part Line Wear

Part line wear occurs at the interface where two halves of the Mould meet. This line, known as the parting or sometimes the split line, is subjected to significant stress during each Moulding cycle.

Over time, the repeated clamping and injection forces can cause erosion, deformation, or misalignment of the parting surfaces. Colloquially this can be called “hobbed over”.

Common Causes of Part Line Wear:

High Clamping Force: Excessive clamping force can exacerbate wear by increasing friction and pressure at the parting line.

Material Properties: Abrasive or filled materials, such as glass-filled plastics, can accelerate wear.

Misalignment: Poor alignment of the Mould halves results in uneven wear patterns.

Injection Pressure: High injection pressure can push material into the parting line, causing erosion.

Inadequate Lubrication: Lack of proper lubrication can increase friction, leading to faster wear.

Effects of Part Line Wear

Unchecked part line wear can have significant consequences on the Moulding process and the quality of the finished parts.

Flash Formation: Worn parting lines allow molten plastic to seep out, creating excess material, or flash, on the edges of parts. In extreme cases this sharp fin of plastic can cut the skin.

Dimensional Inaccuracy: Wear can lead to misalignment, resulting in parts that do not meet dimensional tolerances or fail to fit or function together as when the tool was new and approved for release into production.

Increased Maintenance Costs: Frequent repairs and adjustments to address wear add to operational costs.

Reduced Tool Life: Excessive wear can shorten the lifespan of the Mould, necessitating early replacement.

Production Downtime: Addressing part line wear often requires halting production, leading to lost productivity.

Strategies to Manage Part Line Wear

Managing part line wear involves a combination of preventive measures, regular maintenance, and design considerations. Here are some effective strategies:

1. Optimise Clamping Force

Excessive clamping force is a primary contributor to part line wear. Ensuring that the clamping force is set correctly can significantly reduce stress on the parting line.

Use Appropriate Force Settings: Adjust the clamping force to match the requirements of the part and material.

Regular Calibration: Periodically calibrate the Moulding machine to maintain optimal force settings.

Monitor Clamping Pressure: Use sensors to track clamping pressure and identify potential issues early.

2. Choose Wear-Resistant Materials

The selection of materials for both the Mould and the Moulded parts can impact part line wear.

Hardened Tool Steels: Use tool steels with high hardness and wear resistance for the Mould surfaces.

Coatings and Treatments: Apply surface treatments such as nitriding, PVD coatings, or hard chrome plating to enhance wear resistance.

Material Compatibility: Avoid using overly abrasive or filled materials when possible. When not possible, like glass filled nylon for structural parts, choose tool cavity materials that will provide resistance to abrasive materials and provide longevity.

3. Ensure Proper Mould Alignment

Misalignment of Mould halves is a common cause of uneven wear. Ensuring proper alignment is critical for reducing stress on the parting line.

Alignment Features: Use precision alignment pins and bushings to ensure accurate positioning.

Inspection and Adjustment: Regularly inspect alignment features and make adjustments as needed.

Machine Setup: Ensure that the Moulding machine is properly levelled and aligned.

4. Control Injection Parameters

Injection pressure and speed play a significant role in part line wear. Controlling these parameters can prevent excessive stress on the parting line.

Optimise Injection Pressure: Use the lowest pressure necessary to achieve complete filling without defects.

Adjust Injection Speed: Slower injection speeds can reduce the impact force of the material on the Mould.

Use Valve Gating: Implement valve gating to control material flow and minimise wear at the parting line.

5. Implement Regular Maintenance

Preventive maintenance is essential for identifying and addressing part line wear before it becomes a major issue.

Scheduled Inspections: Conduct regular inspections of the parting line and Mould surfaces for signs of wear.

Cleaning and Lubrication: Keep the Mould clean and properly lubricated to reduce friction and wear.

Polishing and Repairs: Polish worn areas to restore surface smoothness and prevent further deterioration.

6. Design for Durability

Good Mould design can significantly reduce the risk of part line wear.

Uniform Parting Line Pressure: Design the Mould to distribute clamping force evenly across the parting line.

Avoid Sharp Edges: Rounded edges and corners reduce stress concentrations.

Vent Placement: Ensure adequate venting to prevent material from being forced into the parting line.

7. Use Monitoring Systems

Advanced monitoring systems can provide real-time data on Mould performance and wear patterns.

Wear Sensors: Install sensors to detect wear or misalignment early.

Process Monitoring Software: Use software to track key parameters such as clamping force, injection pressure, and cycle times.

Data Analysis: Analyse data trends to predict and prevent potential issues.

Benefits of Managing Part Line Wear

Effectively managing part line wear offers numerous benefits, including:

Improved Product Quality: Consistent parting line integrity ensures high-quality parts without defects.

Extended Tool Life: Proper maintenance and management reduce wear, prolonging the lifespan of the Mould.

Reduced Operational Costs: Minimising repairs, maintenance, and scrap lowers overall production costs.

Increased Productivity: Fewer interruptions for maintenance and repairs lead to higher uptime and output.

Sustainability: Reducing scrap and extending tool life contribute to

more sustainable manufacturing practices.

Part line wear is an inevitable challenge in injection Moulding, but with the right strategies, its impact can be minimised. By optimising clamping force, selecting wear-resistant materials, ensuring proper alignment, and implementing regular maintenance, manufacturers can prolong tool life, maintain product quality, and reduce operational costs.

Advanced monitoring systems and thoughtful Mould design further enhance these efforts, making part line wear a manageable aspect of the injection Moulding process.

With proactive management and a focus on preventive measures, manufacturers can ensure that their injection Moulding tools remain efficient and reliable, supporting long-term success in a competitive industry.

Another choice that will impact many of the points above is your choice of toolmaker and moulder. In tooling and moulding, like most areas in life – you get what you pay for…..

My favourite quote from my mentor Geoff Crumblin- "You can't make a silk purse from a pigs ear".

My hope is this information provides knowledge and confidence to assess your choices and decisions for a closer working relationship with your chosen supplier.

---

équipe design & consulting is a Product Design Consultant in Sydney with 20 years experience in design and manufacture of Medical grade moulded parts and product, including 5 years at the coal face as Operations Manager at a world class medical grade moulding facility; we are specialist in Design for Manufacture (DFM).

Please reach out if you feel you need assistance with your part design for plastic injection moulding.

We offer Design Coaching and Guidance to Full Service Design Consulting.

#Designforplasticinjectionmoulding #DesignForManufacturing #DesignThinking #DesignforManufacture #DesignConsulting #DesignCoaching #equipedesign #DesignforAssembly #IndustrialDesign #CREODesign

References: ChatGPT, Google Images

Comments